Three Ways Enzyme Kinetics Dictate Glucose-Sensor Accuracy

Why kinetics come first

Every reading your glucose strip or CGM produces begins with a single catalytic event. If that event happens too slowly, too fast, or under the wrong conditions, accuracy drifts and ISO 15197 compliance slips. Three kinetic parameters-Km, kcat, and oxygen-dependence (or lack thereof)-do most of the damage. Nail them early and downstream verifications move faster; miss them and you will bleed time in redesigns, re-calibration, or regulatory queries.

Below we unpack each parameter, show how it skews performance in the real world, and outline proven levers-many of which BBI’s enzyme portfolio already puts at your fingertips.

1. Match Km to the Clinical Range to Protect Linearity

What goes wrong

Km is the glucose concentration at which the reaction rate is half of Vmax. Wild-type A. niger GOx sits in the 33–110 mM band—comfortably above physiological glucose—so signal remains proportional across 1–25 mM blood levels. Drop into an engineered low-Km oxidase and you risk saturating the enzyme around 15 mM, compressing the upper half of your calibration curve and producing high-bias readings in hyperglycemia.

Control Levers

| Lever | How it helps | How to apply |

|---|---|---|

| Select higher-Km enzymes | Preserves linearity at high glucose | Stick with classic GOx or choose GDH-FAD variants engineered for Km ≈ 60 mM |

| Tune enzyme loading | Higher load offsets a high Km to recover low-end sensitivity | Data-log strip current vs. glucose at multiple loadings; pick the knee that meets both ends of the spec |

| Blend or mutate | Combine high-Km backbone with affinity-boosting mutations only where needed | BBI offers multiple grades of GOx so you can screen without starting a protein-engineering project |

Quick Check

Plot sensor signal vs. 0–30 mM glucose after five seconds. If the slope falls off before 20 mM, reassess Km or mediator diffusion.

| Observation | Why it matters |

|---|---|

| Linear slope across 0–30 mM at 5 s | Confirms the assay is still enzyme-limited, so sensor output is proportional to glucose in the clinically relevant band. |

| Early slope roll-off (<20 mM) | Flags either: • Km too low → enzyme is already at Vmax and can’t report higher glucose • Mediator/glucose diffusion limit → electrons or substrate can’t reach the enzyme fast enough |

Additional Quick-Check Tips

- Run duplicate strips in 5% O₂ and 21% O₂

- If only the low-O₂ data go nonlinear, the culprit is oxygen dependence (GOx).

- If both curves break, focus on Km or mediator concentration.

- Log current density (µA cm⁻²) vs. glucose, not raw meter output

Normalising for electrode area makes results portable between lab cells, pilot strips, and production lots.

Some caveats to remember:

- Integration vs. snapshot: Some meters integrate charge over 5 s rather than reading an instantaneous current. If yours does, set your potentiostat integration window to match.

- Temperature drift: Km and diffusion coefficients shift with temperature. Keep the plate at 30 ± 0.5 °C or run at both 25 °C and 37 °C so surprises don’t appear during stability trials.

- High-glucose edge cases: ICU and dialysis samples can exceed 30 mM; consider extending the curve to 40 mM if those markets matter.

You’ll know within half an hour whether to tweak Km by picking a different enzyme grade or to open the mediator/diffusion throttle instead.

2. Exploit kcat without breaking diffusion limits

What goes wrong

Higher turnover (kcat) shortens response time, but only until the reaction becomes limited by glucose or mediator diffusion. PQQ-GDH clocks 5 000–10 000 U mg⁻¹-≈25× GOx-yet if the strip’s diffusion path can’t feed it, signal plateaus early and meter electronics mis-time the endpoint.

Control levers

- Calibrate kcat to strip architecture – For a five-second finger-stick meter, activity around 700 U mg⁻¹ (modern fungal GDH-FAD) hits time-to-read targets without starving itself.

- Right-size enzyme mass – Fast enzymes need less protein; trimming load lowers strip cost and reduces batch-to-batch variability.

- Balance mediator kinetics – A kcat boost is pointless if the ferro/ferricyanide couple lags; adjust mediator concentration to keep the electron shuttle rate higher than Vmax.

BBI advantage

Because BBI manufactures multiple grades of GOx and GDH under ISO 13485, you can order the same activity grades you screened in R&D at production scale-avoiding the “re-code every new lot” headaches of commodity supplies.

3. Remove oxygen dependence to erase altitude and haematocrit bias

What goes wrong

GOx consumes O₂. At high glucose or low ambient O₂ (capillary specimens at altitude, CGM tissue sites), the reaction slows, artificially lowering readings. Mediated strips reduce but do not eliminate the effect; CGMs feel it most because tissue O₂ is ~⅓ arterial.

Control levers

- Go oxygen-independent. Modern GDH-FAD transfers electrons directly to a mediator, making the assay insensitive to O₂ swings-if interference is engineered out.

- Engineer specificity back in. Protein-engineered GDHs now match GOx’s glucose exclusivity [reference specificity of a BBI GDH product].

- Validate under stress. Run accuracy panels at 5 % and 21 % O₂, across 20-60 % haematocrit. If bias changes by > ±2 mg dL⁻¹ between conditions, revisit enzyme choice.

Pulling it together-A kinetics checklist for your next design review

- Map Km vs. clinical range – ensure proportionality at the extremes.

- Benchmark kcat to diffusion – faster isn’t always better.

- Stress-test oxygen effects – if GOx passes, fine; if not, move to GDH.

- Lock supplier consistency – insist on ISO 13485, batch COAs showing activity and Km.

- Document lot-control strategy – regulators want traceability as much as accuracy.

Where to go deeper

This post cherry-picked the highlights. The full whitepaper “Optimizing Enzyme Kinetics for Glucose Determination in Diabetes Assays” contains:

- Comparative Km/kcat tables for 9 enzyme variants

- Shelf-life curves for stabilised vs. unstabilised formulations

- Regulatory checklists you can paste into a 510(k)

- All the data sources

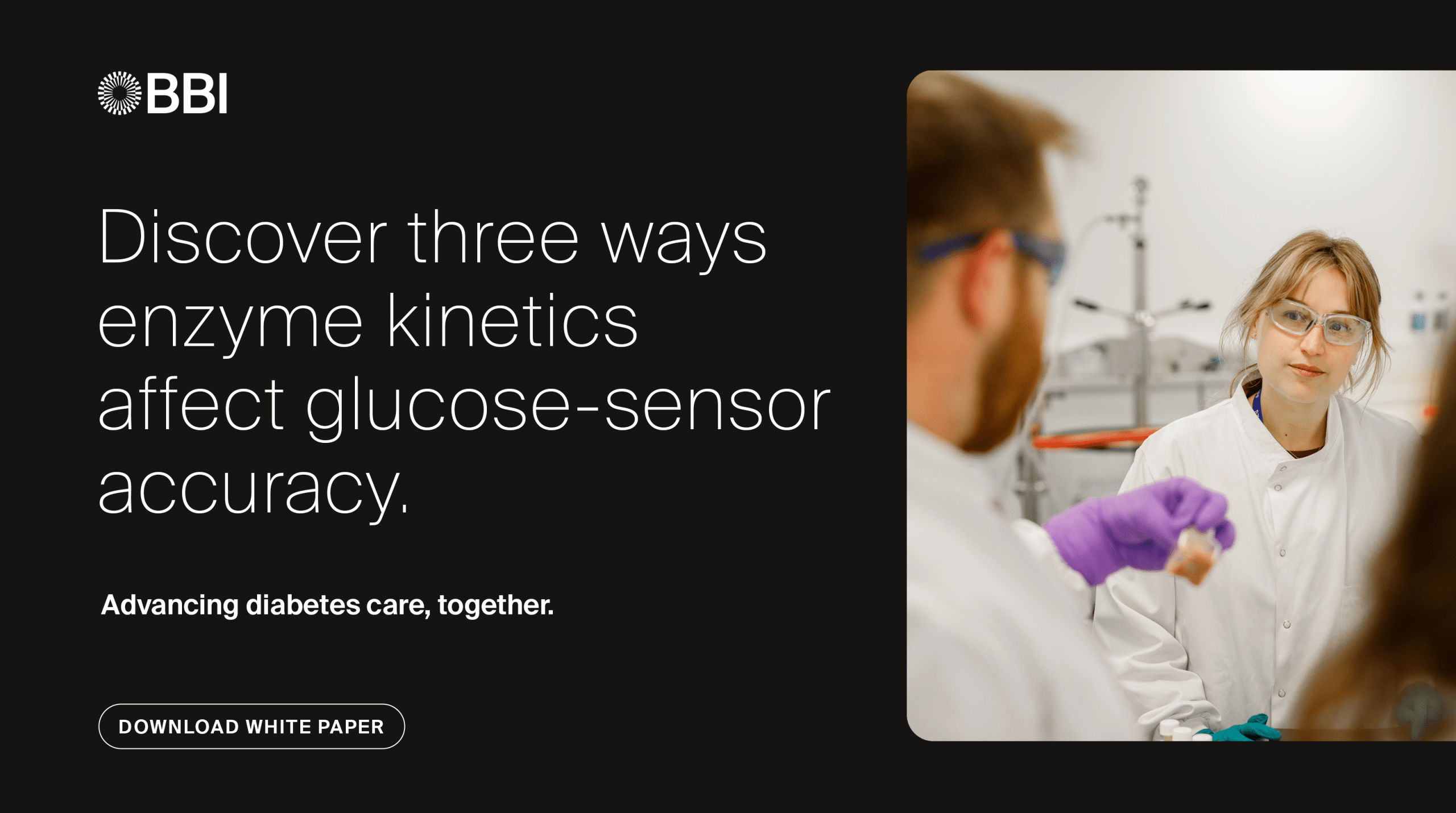

Want the full picture? Download our free White Paper on diabetes biosensors for deeper insights.